Keyed Components

There are three types of construction components: Keyed Brick™, Keyed Cell™ and Keyed Ply™. The Keyed Brick builds walls with horizontal connections. The Keyed Cell is a multi layer component that assembles into flat or dome Keyedcombs™. The Keyed Ply is a sandwich layer that assembles into flat Keyed Panels™ or curved Keyed Tubes™. The starting goal is to make plastic injection Keyed Brick construction components for walls, intersections, corners, and frames for windows and doors.

There are US patent pending; PCT patent filing in Canada and EPO.

The Basics

The Key Thread profile has a front or back wedge shape that adds a unique “hook” with a more spherical resistance. Because of that hook, Key Threads can be applied to cylinder, cone or disk shapes; and follow the curves of a convex, concave and other surfaces. The Key Thread constantly increases in size. When engaging, it is loose and then all surfaces engage at that the same instant. The difference between the male and female surfaces is fabrication tolerance.

There are three planes the Keybrick is configured on. The most common has been the XY plane. The others will be for intercepts and tight connections where XY does not work well.

There are three Keyed Components: Keyed Bricks, Keyed Cells and Keyed Plys. These have different Key Thread configurations and more layers add strength.

The starting product lines are the Keyed Bricks, Keyed Cells and Keyed Plys. The Keyed Bricks have disk threads on the top and bottom; and cylinder threads on the ends. Keyed Cells make honeycomb-like structures using cylinder or cone threads. Keyed Plys are layers of disk threads similar to plywood. It has a base and finished layer with multiple sandwich layers between.

Keyed Bricks™

Keyed Bricks are the first application to be developed. The easiest would be solid Bricks but plastic injection is limited by how parts cool and is more predictable with the thin walls of a shell. That hollow shell will be filled with a structural load bearing material. That shell can be made from recycled plastics, metal, ceramic or anything that can form this outer casing and hold the load bearing contents. That contents could be composites of plastics, sand or cement contained in an insert. The material choices depend on the structural and design needs.

A standard Keyed Brick can be modified for a vertical curve or horizontal curve to build arched or rounded walls.

The standard Keyed brick rotates on an XY Plane. Other configurations rotate on an XZ plane and YZ plane. These are either aesthetic design choices or configured where the standard Keyed Brick does not fit, is hard to assemble or needs more strength relative to how stresses are distributed.

Keyed Bricks have cylinder Key Threads on the ends and disk Key Threads on the top and bottom; each brick is identical. They can also have corners or wedge shape for transitioning into a vaulted ceiling.

Keyed Cells™

Keyed Cells are cylinder and cone Key Threads. Cylinder cells are like honeycomb cells and they assemble into Keyedcombs; and each cell is identical. They distribute stress laterally for floors and ceilings. Cone cells are curved and assemble into Keyedomes; these cells are identical per unique layer. They are similar to geodesic spheres.

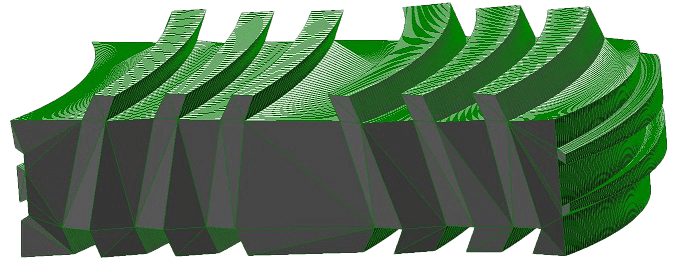

Keyed Plys™

Keyed Plys use disk Key Threads like plywood for larger sheets. Flat plys assemble into Keyedpanels™; each ply is identical. Curved Keyed Plys assemble into Keyedtubes™; these plys are identical per unique layer. Keyedtubes can be from one foot to several feet in diameter for water and sewage drainage systems.