Turn Plastic Waste

into something people want to use.

We have developed a technology that will use some of the 350 million tons of global plastic waste to make a product line of construction components that is easy for people to build with. Similar parts will be made out of concrete.

Overview

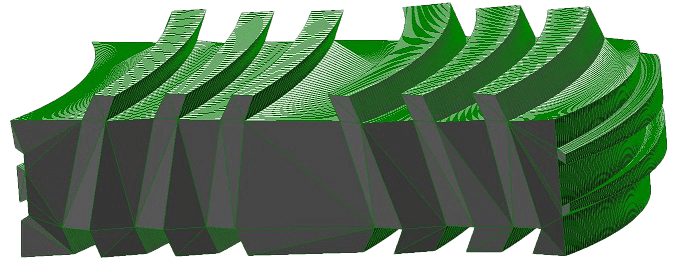

The new connection technology is called a Key Thread. Software engineers can take these threads and apply them to construction components that can be 3D printed. There will be 3D printed molds. Both part and mold files will have machining software that generates the Gcode for 5-axis tool movements. This is the foundation for making many of the parts, molds and machinable applications. The part files are be uploaded to Finite Element Analysis (FEA) for optimizing their design. I have done all of this before on three other new threads that I could not commercialized.

The Next Evolution of Building Materials

Plastic waste is a global problem that needs new materials and products that will consume it.

(more)

Plastic sand is a new material that consist of plastic as a binder and sand as an aggregate

Keyed Bricks are construction components made out of plastic sand that are easy to assembled

(more)

Create a keyed brick marketplace

(more)

- Keyedassembly for virtually building Keyed Brick structures

- KeyedScape for selling the virtual structures

- 3D print scaled keyed brick models to assemble small keyed structures

Create the delivery system

(more) (engineering cost breakdown)

- Build the machinery

- Start the first Keynector business

- Franchise Keynectors

Supporting

Finite Element Analysis – independent proof of fastening by four interlocks.

(more)

Future products:

(more)

Incredible Numbers

Plastic Waste

The world produces around 350 Million Metric Tons of plastic waste every year.

Recycling

On average, just 9% of plastic is collected for recycling.

On the Rise

Ocean Plastic Pollution On Track to Rise to 29 Million Metric Tons by 2040.